Fermentation Analysis of Silages

Fermentation Analysis of Silages

Most commercial laboratories can analyze forages for the concentrations of various acids produced during the fermentation process. These values can be used to determine the quality of fermentation that has occurred. However, these results cannot be used to balance rations. Taking in combination with nutrient concentrations, they can help explain what did or did not occur during the fermentation process and possibly may explain feed intake problems in dairy herds. For accurate results, samples of forage need to be frozen immediately after being collected and shipped on ice for next day delivery to the forage testing laboratory.

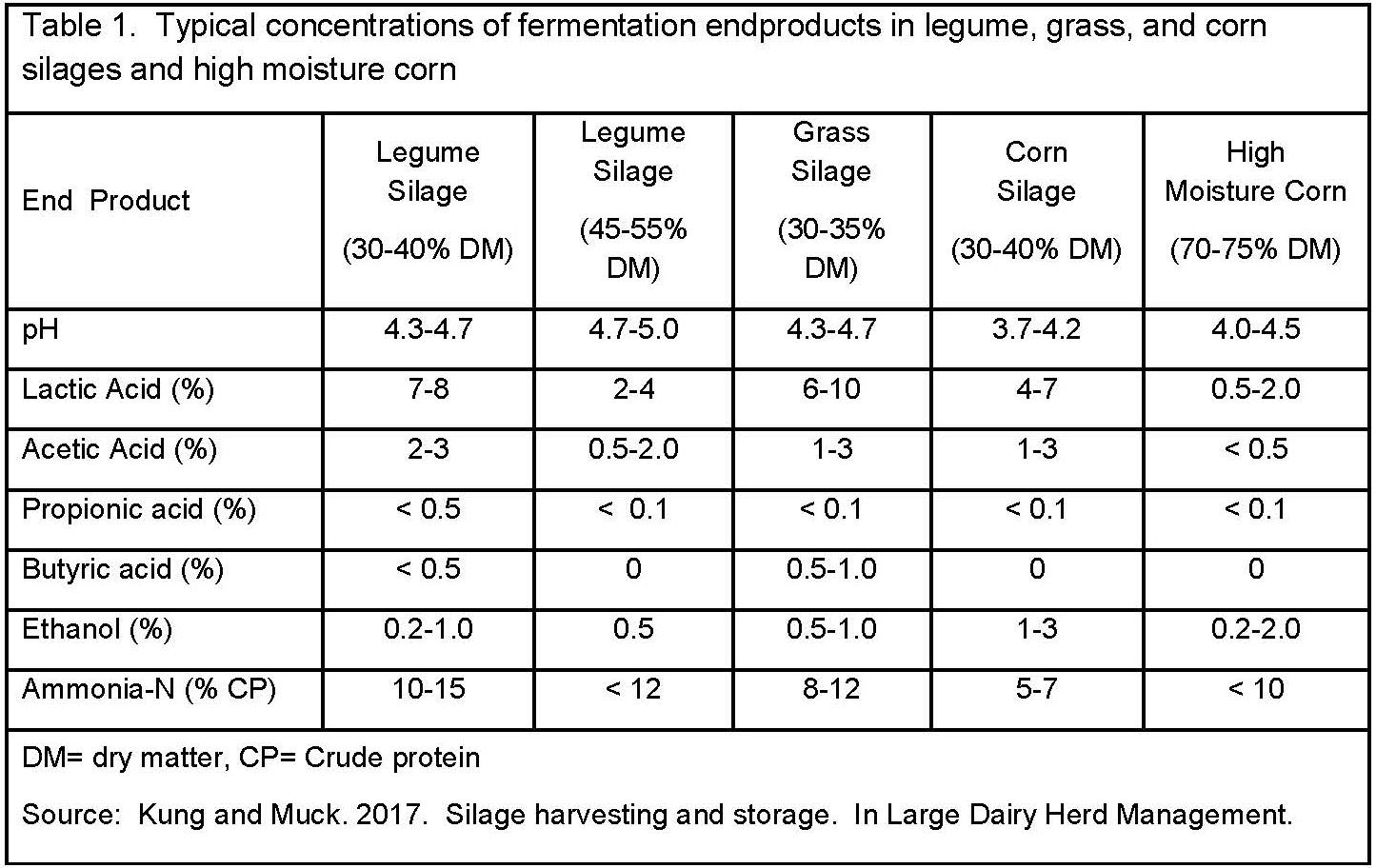

These reports typically analyze the following with expected ranges given in table 1.

pH – Generally, the lower the pH the better the fermentation (assuming pH is within expected ranges) and is one of the key criteria in evaluating the quality of silage fermentation. When pH is higher than expected, fermentation may not be optimum. One possible cause for a higher silage pH is drier silages as fewer acids are produced. In addition, silages that are undergoing a clostridial fermentation have a higher pH as the lactic acid is being converted to butyric acid.

Lactic acid – Lactic acid is the predominant fermentation acid and should comprise 65 to 70% of the total acids in the silage. Generally, the presence of high levels of lactic acid indicates an efficient fermentation and minimal dry matter losses.

Acetic acid - Acetic acid provides silages with the characteristic vinegar odor and taste and helps maintain aerobic stability, i.e. extend bunk life. Some microbial inoculants (Lactobacillus buchneri) increase the amount of acetic acid in silage and help extend bunk life once the silage is exposed to air.

Propionic acid - Propionic acid produces a sharp sweet smell and taste. Generally, this acid is found in very low concentrations in well-preserved and fermented silages.

Butyric acid - Butyric acid produces a rancid butter smell and taste. High concentrations (greater than 0.5%) indicate the silage has undergone an undesirable, Clostridial fermentation and the resulting silage is lower in nutritive value because soluble nutrients have been degraded. These silages may result in lower feed intakes and milk production by dairy cattle. The butyric acid concentration in clostridial silages increases over time. Butyric acid may induce ketosis and should not be fed to early lactation and transition cows. Cows later in lactation can handle 100 g butyric acid daily in their total diets and use of these high butyric acid silages may need to be limited so as not to exceed these amounts.

Ethanol - Ethanol produces an alcohol smell and is primarily an indication of yeast activity. These silages are more prone to spoilage and, as a result, heat quicker with a shorter bunk life. Yeast numbers can double within 2 hours, thus numbers can increase rapidly, further deteriorating the quality of silages being fed.

Ammonia nitrogen - High concentrations of ammonia in silages are an indication of excessive breakdown of proteins caused by a slow drop in pH or Clostridial fermentation. Proper balancing of rations for ruminally degradable protein (RDP) can help minimize problems with dairy cattle at feedout.

Author: Donna M. Amaral-Phillips

![]() Printable PDF version

Printable PDF version