Increase Milk Production with Appropriate Kernel Processor Settings

Increase Milk Production with Appropriate Kernel Processor Settings

Corn silage harvested with a kernel processor, or a chopper roller mill, can increase dairy cow milk production by 4 pounds of milk per day when compared to corn silage harvested without a kernel processor. Corn silage is energy dense and 65% of the total energy in the silage is found in the grain. Of this 65%, seventy percent of the energy comes from the starch stored in the grain. The rest of the energy is derived from the fat and protein content of the grain. By breaking the corn kernel, more starch is more readily available to the rumen bacteria. These bacteria use the starch to make products that provide energy for the cow to produce milk. When harvesting corn for silage, the goal is to harvest a healthy plant with more readily available starch content. However, before the corn harvest can even begin several steps should be taken ensure a successful harvest and kernel processing.

Determine the Kernel Milk Line

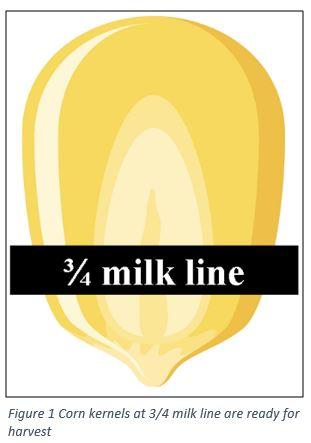

Corn silage should be harvested at peak maturity when the corn kernel is well dented but before the leaves turn brown and dry. Harvest healthy plants when the corn kernels are at ¾ milk line (when using a kernel processor) or greater than 62% whole plant moisture (32 to 38% dry matter).

To determine the location of the milk line in the corn kernel, break several ear samples in half

- Evaluate the milk line on the half that contains the ear tip

- To ensure the location of the milk line, bite a single kernel near the top until the hard starch area is reached.

The hull or pericarp of the corn kernel traps/protects the starch within the grain. Improving access to the protected starch improves digestion by rumen bacteria or intestinal enzymes. A kernel processor properly maintained and used during harvest can increase the ruminal starch digestibility of corn silage by damaging/cracking the corn kernel. The increased access to kernel starch increases the starch digestibility of the harvested corn silage.

Getting Ready for Harvest

□ Check chopper knives

□ Check shear bar

□ Check roller wear

□ Replace all worn parts

□ Check roller mill gap

Two to three months before harvest begins, service the chopper so that needed maintenance is performed prior to harvest window. To ensure the entire chopper is in good condition, replace nicked knives and the shear bar if the edges are smooth. If the rollers are showing signs of wear, replace them. The average life of chromed roller mills is approximately 60,000 tons of corn silage. Irregular wear of the roller teeth can prevent the narrowing of the roller mill gap, resulting in insufficient damage to the kernel, which can lead to reduced starch digestibility for the cow.

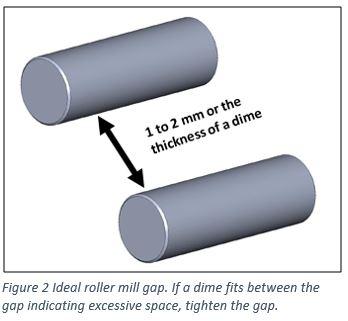

Once worn knives and rollers are replaced, the ideal gap setting for the rollers should be 1 to 2 mm in order to properly crack corn kernels. A quick way to check the width of the gap is to use a dime. A dime is 1.2 mm thick. Place the dime between the rollers and if excessive space is found tighten the roller mill gap (Figure 2).

During Harvest

The Corn Silage Processing Score was developed at the US Dairy Forage Lab to better assess kernel processing effectiveness. In the laboratory, the corn silage processing score is determined by drying a sample of corn silage and shaking the dried sample through a series of sieves. The percentage of starch/corn kernel pieces that pass through a 4.75 mm sieve is measured. Optimum kernel processing of fresh corn silage samples is associated with 70% of starch passing through the 4.75 mm sieve. One drawback for this lab procedure is the delay in results as adjustments to the kernel processor should be made while harvest is proceeding.

When chopping corn silage with a kernel processor, the length of chop should be set to ¾ inch. A longer chop (1 inch) has not been shown to be beneficial. Chop length should be evaluated at the start of the season and throughout the season.

To assess successful kernel processing in the field, Pioneer and Dr. Ferreira (now at VA Tech) developed a fast and easy method to inspect kernel processing success during harvest. This method assesses the number of unbroken corn kernels in a small sample. This procedure should be done with at least 3 loads when evaluating if the kernel processor is effectively breaking up corn kernels and cobs.

- Scoop a sample of silage in to a 32-ounce cup

- Spread the silage on the ground

- Count the number of whole or half kernels

- Corn cob slices/pucks should be broken up into no fewer than 8 pieces

| Whole or half kernels per 32 oz. cup | Kernel Processing Quality |

| ≤ 2 | Ideal processing |

| 2 to 4 | Adequate processing |

| ≥ 5 | Adjustments required |

Table 1 Corn silage chop and kernel processing assessment goals using 32 oz. cup

Assessing the kernel processing of each chopper/ kernel processor several times per day is crucial to ensure consistent kernel processing. Ideally, at least 3 separate cup-samples hourly or at a bare minimum before meal breaks, during short breaks, and at the end of the day (adjustments can be made before the next morning) should be assessed.

If the results of kernel processing are not monitored during harvest, starch digestibility may be reduced. Once the silage is chopped and stored, fixing any mistakes made during harvest is very difficult. Realize that starch digestibility increases with storage length, but the starting point for digestibility is lower when improperly processed kernels are ensiled.

Take Home Messages

Successful kernel processing of corn silage can increase milk production by 4 pounds per day, when compared to corn silage harvested without a kernel processor. Successful kernel processing during harvest can reduce the amount of grain found in the manure and increase the total tract starch digestibility, allowing the cow to convert more of the starch available in the harvested silage into milk.

Two to three months before harvest, make sure the chopper and attached kernel processor are in working order. Replace any worn roller mills and knives. During harvest, check the effectiveness of kernel processing using the 32-ounce cup method where no more than 2 kernels are undamaged. Check the roller mill gap quickly using a dime, to ensure the gap is between 1 and 2 mm. If excessive space is found, tighten the gap.

Authors: Michele Jones and Donna M. Amaral-Phillips