Chapter 4 - Introduction

Chapter 4 - Introduction

The main objective of the broiler industry is the production of SALEABLE chicken meat. To this end, it is important to minimize the number of condemnations at the processing plant and to maximize meat yield.

The main objective of the broiler industry is the production of SALEABLE chicken meat. To this end, it is important to minimize the number of condemnations at the processing plant and to maximize meat yield.

To produce a quality chicken meat product from a live broiler involves a series of efficiently-performed, specific tasks completed in a sanitary manner. Before broilers can be processed, they must be raised to market age, caught, cooped, transported and held, then unloaded at the processing plant. Inside the processing plant, broilers are hung on shackles, stunned, bled, de-feathered, eviscerated, inspected, chilled, graded, packaged and shipped. Because of the complexity of production and processing procedures, several factors may reduce carcass yield and carcass grade.

Defects resulting in carcass downgrading and product losses are caused by diseases, damage to the broiler before slaughter, or maladjusted equipment and manual errors during processing.

Individual carcass inspection is performed by trained government personnel responsible for ensuring that only wholesome poultry and poultry products, fit for human consumption, reach the market place. Licensed inspectors may be veterinarians or individuals specifically trained to carry out the process.

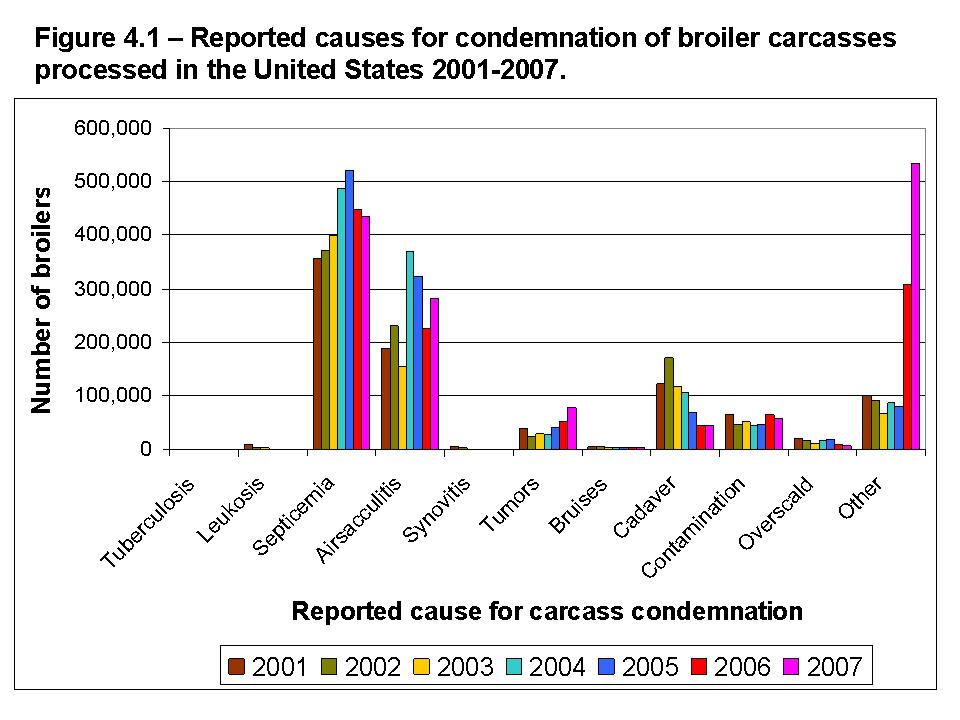

Figure 4.1 below enumerates the most commonly reported causes for condemnation in broiler complexes in the United States. Typically, the main reason for condemnations is septicemia. Both the grower and the processor can play a role in minimizing these costly losses. It is important that biosecurity protocols are developed and implemented in all sections of the broiler industry, including breeders, hatchery, feed mill, grow-out facilities, live-haul, and processing.