What is the Optimum Stocking Density for Your Housing System?

What is the Optimum Stocking Density for Your Housing System?

Determining the optimum stocking density for a group of dairy cows involves balancing the space needs of a group of cows with potential income or profit per stall or 100 sq. ft of bedded pack space. From a cow standpoint, stocking densities at 100% (1 stall or > 100 sq. ft bedded pack) result in the best performance. Dairy cows need 10 to 14 hours to rest and this is optimized when they do not have to wait for a stall to lie down. However, depending on milk and feed prices and stage of lactation of the cows in the group, a stocking density of 100% may not result in the most profit. Many factors should be considered to determine the optimum stocking density. These factors are discussed in this article.

Impact of Stocking Density on Performance

Stocking densities over 100% can decrease milk production, decrease milkfat percentage and yields, and increase the probability of a cow being culled. Milk production is affected by many factors that, at first glance, do not seem directly related. Increasing stocking density decreases the amount of time cows spend ruminating, increases stress resulting from disruptions in social order, and decreases the amount of time spent resting. Increased rumination time, decreased stress and one additional hour of resting time are each associated with an increase of 2 lbs of milk/cow every day. For a herd of 100 cows, that is at least 200 lbs milk/day or $1,098/month in additional milk income. Stocking rate also impacts milk quality. In a research trial increasing the stocking density to 142%, milk fat percentage was decreased by 0.2% units, and SCC increased at a stocking density of 113%. Additionally, higher stocking densities in the breeding pen could reduce conception rates.

Calculating Ideal Stocking Density

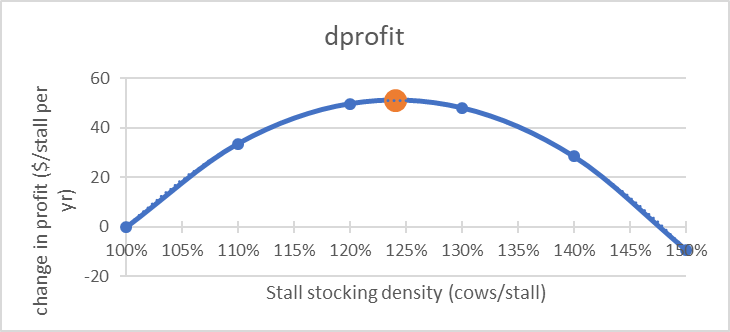

Ideal stocking rate for your specific farm situation can be calculated using the Stall Stocking Density Calculator developed by DeVries and others. In order to calculate an optimum economical stocking density using this tool, milk price and feed cost ($/lb DM) are needed. The tool then outputs a graph that shows a point of optimization in profit per stall per year, as shown below in Figure 1. The orange circle represents the ideal stocking density for a situation where milk is $18.00/cwt and feed costs are $0.12/lb DM.

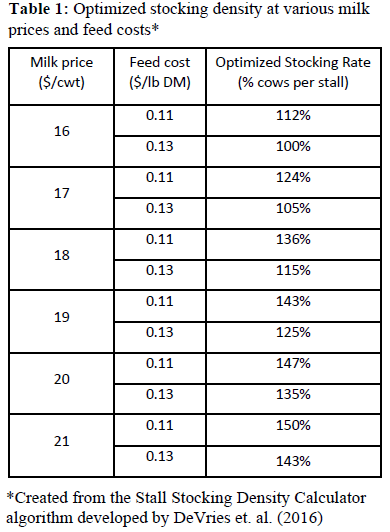

Scenarios for the most economical stall stocking rate based on various milk prices and feed cost are included in Table 1. This table includes combinations that have the most economical stocking density from 100% to 150% based on the assumptions used. As milk price increases, higher stocking densities result in a higher economic benefit. Whereas, at a defined milk price, increasing feed costs decrease the optimum economical stocking density. However, research shows that the ideal stocking rate for most farms to maximize profitability is between 100 to 120%, because the model does not include a variety of cow health and wellness factors that research suggests are affected at a stocking density at or approaching 150%.

Scenarios for the most economical stall stocking rate based on various milk prices and feed cost are included in Table 1. This table includes combinations that have the most economical stocking density from 100% to 150% based on the assumptions used. As milk price increases, higher stocking densities result in a higher economic benefit. Whereas, at a defined milk price, increasing feed costs decrease the optimum economical stocking density. However, research shows that the ideal stocking rate for most farms to maximize profitability is between 100 to 120%, because the model does not include a variety of cow health and wellness factors that research suggests are affected at a stocking density at or approaching 150%.

Do Not Overstock Facilities for Fresh and Close up Dry Cows

Although 100 to 120% may be the ideal rate for a general lactating group, close up and fresh groups require significantly more lying space. Not providing sufficient space for these critical periods can also set up a cow to produce less milk throughout the lactation. Fresh cows are at a decreased risk of transition diseases, such as ketosis, when the stocking density is below 100%. The ideal stocking density for transition cows is at or below 80%. For every 10% increase in stocking rate above 80% for close up cows, milk production in the lactation will be 1.6 lbs per day less. This is a loss of around $90 over a 305-day lactation. This effect is mainly evident in first lactation cows. First lactation cows tend to be in the bottom of the social order, and they are pushed out of the feed bunk or stalls at preferred times, which can cause lowered production. Stocking density of greater than 80% in the transition pen causes adverse effects on production through the first 83 days of lactation in first lactation cows.

Barn Ventilation Impacts Stocking Density

The number of stalls per cow is not the only determining factor for stocking density. Ventilation capacity of the facility is vital in determining stocking density. Ventilation rate for a barn should be calculated based on the maximum stocking density in that barn. Depending on the barn and the climate, natural and mechanical ventilation can be used to create adequate air flow. During the cold parts of the winter, air changes in the barn are needed at a rate of around 4 times/hr. In the summer however, that rate could be 40 to 60 air changes/hr. Inadequate ventilation can lead to unsafe levels of toxic gases, such as ammonia and higher moisture levels in barns. Ventilation is also vital for preventing and abating heat stress, which could be increased with an increased number of cows in a barn.

Stocking Density also Accounts for Feed Bunk Space

By increasing dry matter feed intake (DMI), milk production will also increase. For every 1 lb increase in DMI, milk production may increase up to 2 lbs in early lactation cows. Intake is affected by the amount of feed bunk space each cow receives. The recommendation for feed bunk space is 24 inches for mature lactating dairy cows, 30 inches for fresh cows, and 36 inches for close-up dry cows with post and rail feedbunks. When stocking density results in less feed bunk space per cow, the amount of times in a day that a cow eats decreases and/or rate of eating is changed. This effect is most pronounced at peak feeding times, especially after milking and when fresh feed is delivered. Studies suggest that measuring stocking density using feed bunk space may be a better measurement of cow performance than the number of stalls per cow. Feed bunk space per cow could also be a measure of reproductive performance. Cows with inadequate feed bunk space are less likely to be pregnant at 150 DIM.

Authors: Lilly Robertson and Donna M. Amaral-Phillips