Chapter 7 - Ventilation System Design

Chapter 7 - Ventilation System Design

Ventilation is the exchange of air in a building with fresh air from outside. Heat, moisture, noxious gases, dust and microorganisms are produced in a broiler house as a result of bird metabolism, feeding and drinking activities, waste decomposition, and unvented heating units. Ventilation systems are designed to maintain air quality during cold weather and to regulate temperature during hot weather. Heating and cooling systems compliment ventilation to maintain a productive environment.

Ventilation rate, the amount of air exchanged in a given time, is usually expressed in CFM (cubic feet per minute) per bird or CFM per unit of body weight. It is also expressed as ACH (air changes per hour) which reflects a complete replacement of the building’s air volume during a time period. Ventilation rate is designed to provide a uniform environment that is most suitable for economical poultry production. In practice, however, the environment in a poultry house is always in a transient state due to continuous changes in outside weather conditions; changes in moisture, heat, and manure production rates by birds; and the cycling of mechanical devices such as heaters, fans and feeders. Electronic sensors, environmental controllers and warning systems are used by commercial producers to help ensure that the proper environment is maintained

Ventilation has two basic functions: air exchange and air distribution. Air exchange may be summarized simply as the cycle of fresh air in, stale air out. Air distribution is the process of delivering fresh air to all animals and mixing fresh air with stale air prior to removal from the building. Inlets provide the primary means of controlling air distribution within the ventilation space. Controls for fans, inlets, ridge vents, and sidewall openings allow these components to function together to achieve the desired ventilation performance.

VENTILATION SYSTEM DESIGN VERSUS MANAGEMENT

Ventilation system design deals with sizing and selecting system components (i.e., heaters, inlets and fans) from the many kinds and sizes available. Design procedures consider extreme conditions to ensure that the selected ventilating system components can provide adequate ventilation and environmental control even during extreme weather. Ventilating principles are used for system design.

Ventilation system operation and management deals with day-to-day adjustments of the existing system components in response to current conditions (i.e., weather, bird numbers, and age). Extreme conditions are seldom encountered. The focus is on efficient and effective environmentalcontrol that responds to changing conditions. It is important to understand ventilating fundaments to better manage the ventilating system to provide the most appropriate and economical environment possible.

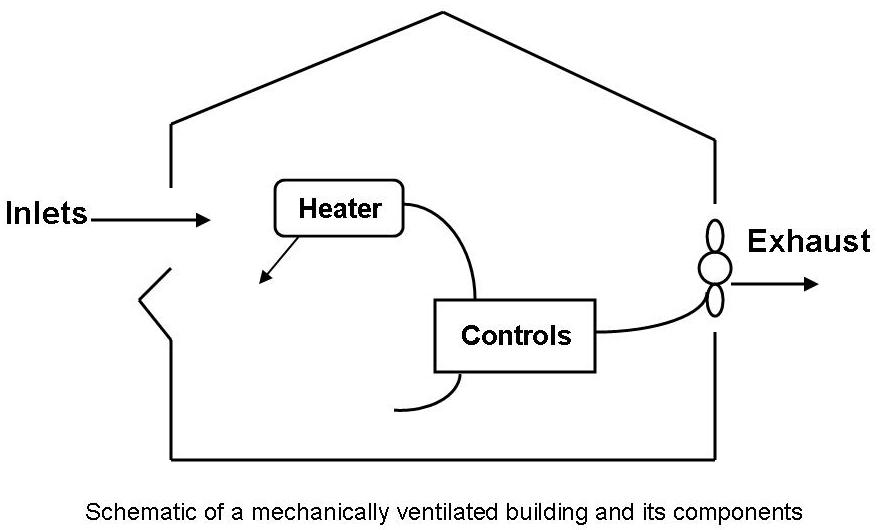

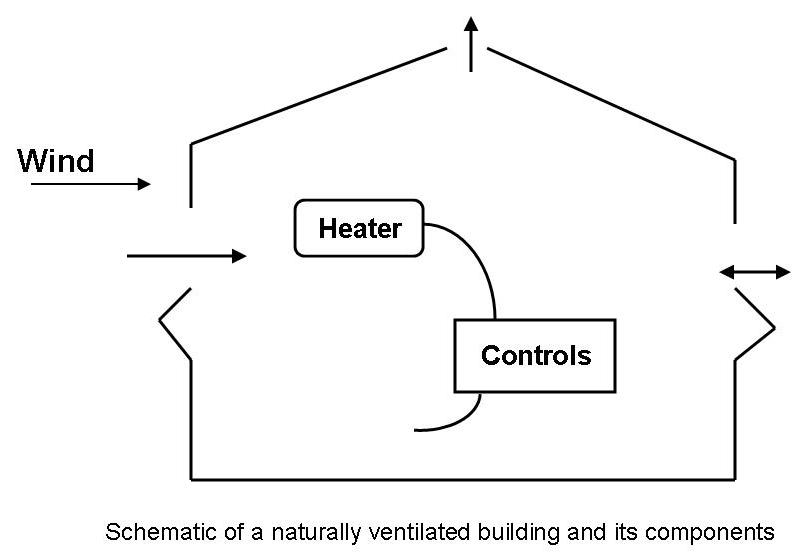

There are two primary types of ventilation, mechanical and natural. Mechanical ventilation uses fans to provide airflow (see Figure 7.9). Natural ventilation takes advantage of naturally occurring forces to move air in and out of the building (see Figure 7.10). In either type of ventilation, a pressure difference causes air to flow and provides the driving force for ventilation. In mechanical ventilation, a static pressure difference between the poultry building interior and the outside is monitored to assure proper air exchange and air distribution. A combined or hybrid system uses both mechanical and natural ventilation.

The design criteria for ventilation rates to maintain acceptable indoor air quality are based on moisture removal. Minimum ventilation ratesfor cold weather are commonly based on air exchange rates that will keep moisture removal balanced with moisture production. It is generally assumed that with proper moisture regulation inside the building, other air components such as dust, ammonia, and carbon dioxide will also be in control.

However, with increased interest in improving the economy of production and the conservation of energy, ventilation rates are often reduced to the point that contaminants are a problem. To keep aerial ammonia below the recommended threshold of 25 ppm (parts per million) when old litter is used, the minimum ventilation rate needs to be up to nine times the recommended minimum ventilation rate.

The higher ventilation rate results in more heat lost in exhausted air and higher supplemental heating costs. Failure to provide a higher ventilation rate will result in poor bird performance due to high ammonia levels. Clearly, air quality, management practices (such as the use of built up litter), and bird productivity are interrelated components of successfully poultry production. (For more information see Chapter 8 on Cold Weather Ventilation).

As building air temperature increases or decreases from the desired inside temperature, the ventilation system, and perhaps heating or cooling, are activated in order to maintain the target temperatures. For example, during hot weather, once the minimum ventilation capacity is reached, the building temperature begins to rise approximately linearly with further increase in outside air temperature. At some point (at which the temperature considered stressful for the birds), cooling mechanisms such as evaporative cooling and tunnel ventilation may be activated.

The relationship between poultry production efficiency and building environment is complex. Further complications arise from the costs associated with maintaining an optimal environment for the bird. Costs are usually proportional to the difference between the desired poultry building environment, on the one hand, and, on the other, the outside air conditions plus the quantity of air contaminants inside the building. It is in the grower’s economic interest to provide the best possible environment for the bird. In fact, most poultry production was moved indoors to provide an optimal year-round environment for birds and workers while benefiting from labor and mechanization efficiencies.

The required ventilation rates for cold, mild or hot weather will be described in future chapters. The entire range of seasonal airflow needs must be integrated into a ventilation strategy based on daily conditions. One solution to variability among seasonal needs is to use single-speed fans that are ‘staged.’ Another is to use variable-speed fans.